Analysing the factors that influence Taurus’ performance, we can’t forget to mention the contact points between the bike and the asphalt: the tires.

In order to maximize the bike speed, we studied the influence of the rolling resistance at the typical speeds reached during the Battle Mountain runs. This study was conducted throughout 2018.

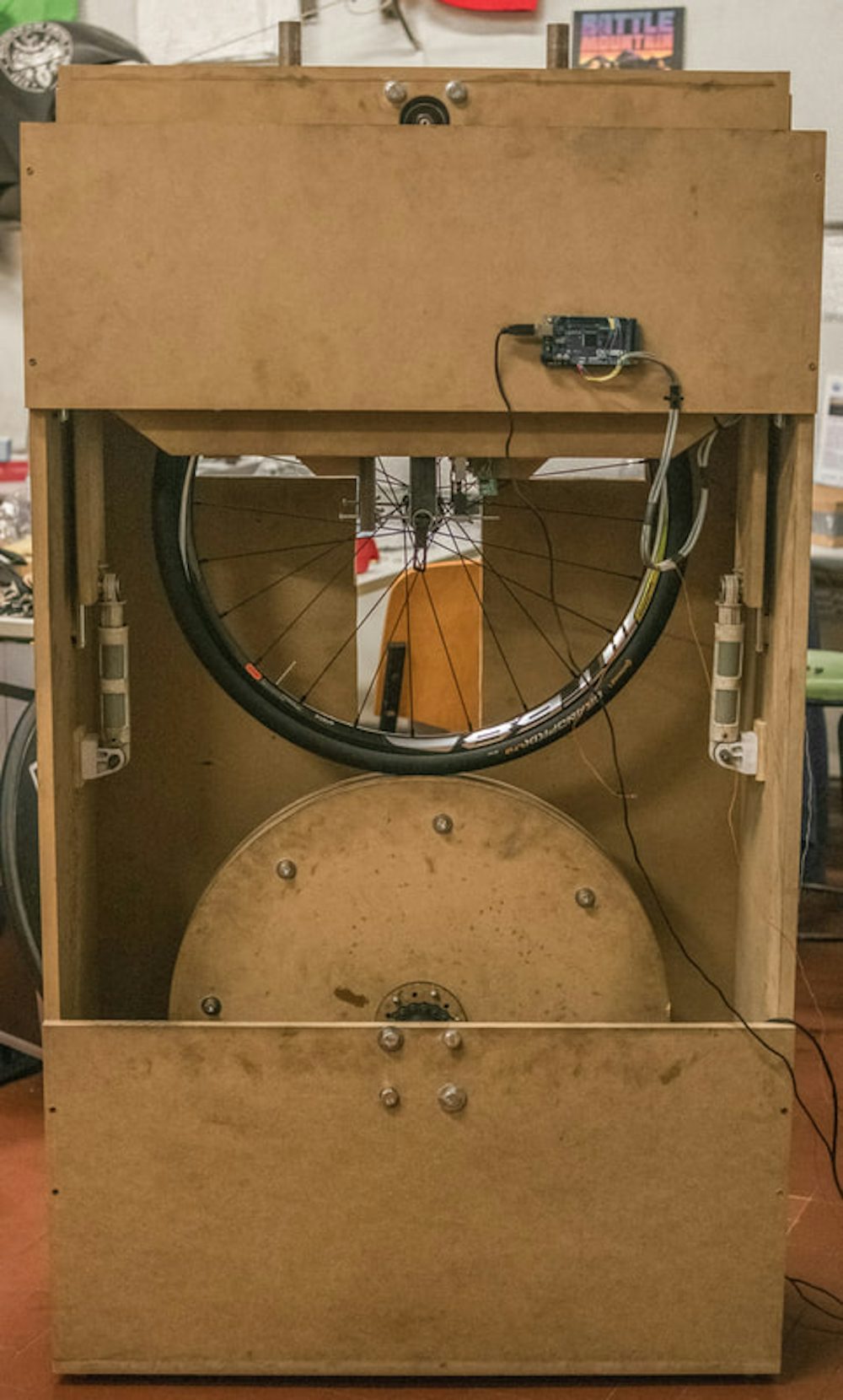

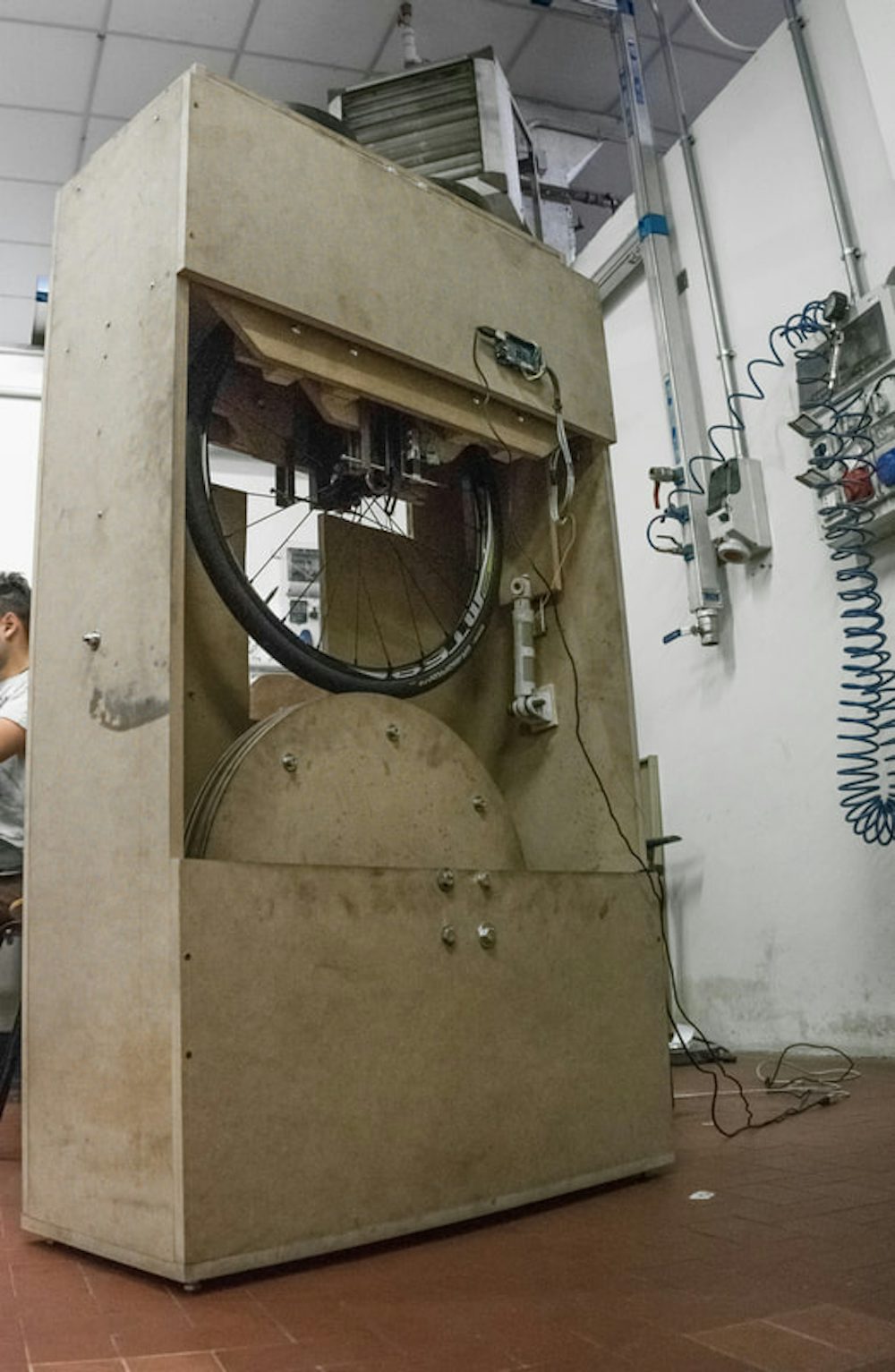

To accomplish this task, our team has initially built a test bench in order to test the combinations of different tires and mounting configurations. How does it work? The test is based on a wheel-on-drum rolling configuration. The bench is composed of an electric motor that moves a 600 mm diameter MDF drum. A wheel is loaded with a weight that simulates half the mass of Andrea and Taurus and is then placed on the MDF drum.

As the drum rotates we measure the electrical power used by the motor at given RPMs. From the measured value we subtract the contributions due to the aerodynamic resistance of the drum and the wheel at that speed in order to obtain only the power dissipated by the rolling of the tires (plus a marginal contribution by the bearings, which is also present on the road).

This power is divided by the angular speed of the wheel in order to obtain the resistant torque. Dividing the torque by the wheel rolling radius we obtain the resistant force applied to the wheel hub. At this point the rolling coefficient is obtained by dividing the resistant force by the applied load.

Finally, using the Clark formula, the effect of the drum curvature is corrected obtaining a more realistic estimate of the rolling coefficient on a flat road. Simple, isn’t it?

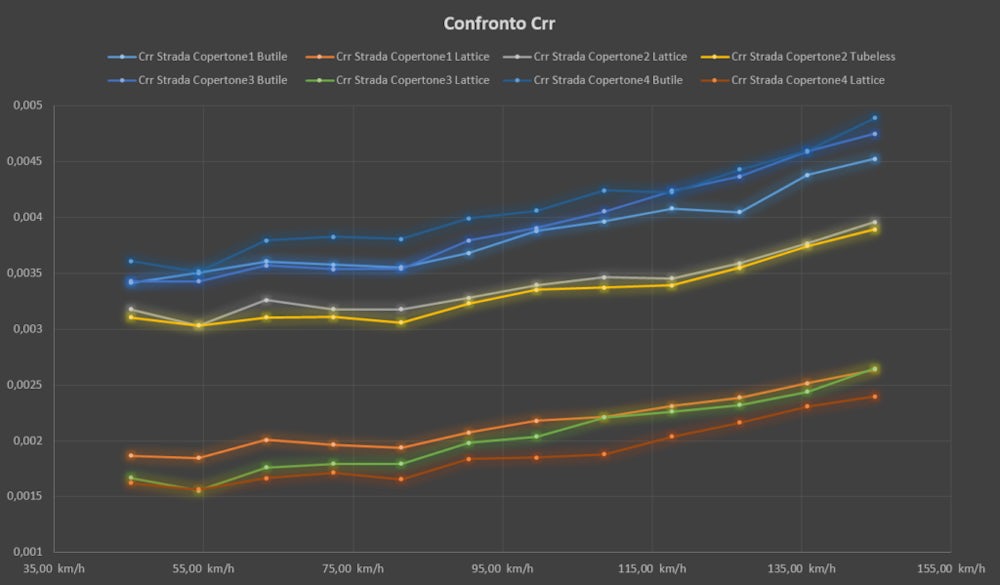

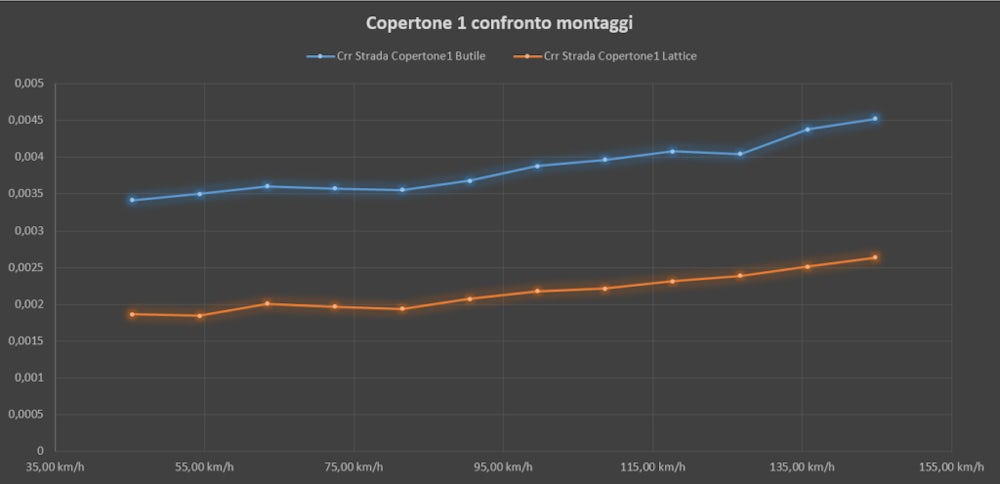

This procedure was repeated for the different mounting configurations and for the different tires we found on the market.

As we can see from the graphs, for each tested tire there is a significant difference between the assembly of the given tire in combination with a latex inner tube or with a butyl inner tube. On the other hand, the difference between a tubeless assembly (without an inner tube) and with a latex chamber is minimal. This is mainly due to the different thickness between the butyl inner tube and the latex inner tube, as well as the different interactions and rubbings that are created between the two different materials and the inside of the tire. Instead of testing them at a constant pressure we decided to test each tire at the maximum working pressure recommended by the manufacturer.

In this way, we were able to have a comparison between the assembly compositions best performances. This decision allowed us to simulate at best the conditions of the Battle Mountain runs.

What has changed for Taurus? With the new configuration we were able to save 27 W per wheel compared to the 2017 set up at record speed.

This measurement system brings with it the inconvenience of the electric motor non-linear efficiency. This behaviour of the motor makes it difficult to separate the effect of its non-linear efficiency from the measured input power to obtain the net power dissipated by the rolling alone. During this year the team has developed a completely new test bench, still based on a wheel-on-drum setup, that provides a different measuring method. In fact, two strain gauges positioned near the wheel hub are used to directly measure the resisting force applied on this point, from which we only need to separate the contribution of the wheel aerodynamics. Moreover, the contribution of the aerodynamics of the drum is irrelevant to this measurement method. Another aspect of the upgraded test bench allows for the testing of wheels larger than the 20” ones mounted on Taurus. This allows us to have an ever increasing understanding of the parameters that characterise the rolling of bicycle tires.